The Spring Festival in 2020, the Year of the Boxer, will remain in the memory of Chinese people in a very unique way. As the whole country prepared to celebrate the Spring Festival, the highly infectious Novel coronavirus broke out in Wuhan, recklessly eroding human lungs and threatening innocent lives.

From the outbreak at the end of 2019 to February 16, 2020, the number of confirmed infections exceeded 70,000, according to the National Health Commission. With strong state intervention, the epidemic has been brought under control, but it is not over. Due to the outbreak of the epidemic, the movement of people is limited, and the service sector is the first to be significantly impacted, especially in offline retail, catering, transportation, tourism and entertainment. As the epidemic continues, its impact is gradually spreading to manufacturing industries such as automobiles and industrial products. Despite the corresponding measures taken by the Chinese government, the epidemic has had an obvious impact on China’s manufacturing and product supply, mainly in the following aspects:

1

For manufacturing enterprises with high sales of consumer products or similar characteristics during the Spring Festival in previous years, such as food and beverage, in the short term, due to the blockage of offline retail channels, the high inventory of pre-holiday preparations cannot be digested, resulting in stagnant sales, resulting in cash flow shortage, and even some imminent products scrapped, directly causing a lot of losses for enterprises. In the medium and long term, the uncertainty surrounding the evolution of the epidemic (Figure 1) will increase as demand changes. According to the “bullwhip effect”, the amplification of demand variation in the supply chain will lead to increased operational difficulties for secondary and tertiary suppliers, especially smes, as well as an increased risk of disruptions throughout the supply chain.

2

For products related to epidemic prevention and control, there is a huge short-term gap. With the surging demand for epidemic prevention products, China has not only increased its global procurement, but also opened a valve to accelerate the production of related products. For example, a large number of automation enterprises in Guangdong are accelerating the development of KN95 mask automatic production line. However, the real problem before us is the lack of end-to-end supply chain management. Take the production of masks as an example. The current situation in the industry is that many new semi-automatic/automatic production lines have been added, which has achieved an increase in production capacity, but the supply of masks is still insufficient. What is the new bottleneck of the whole supply chain? Insufficient supplies of raw materials for mask production, such as melt-blown cloth, and limited medical logistics can be new bottlenecks.

3

Short-term supply chain disruptions increase export uncertainty. Since the outbreak of the epidemic, the average daily coal consumption of the six major power generators has decreased by about 50% from more than 700,000 tons/day in December to 370,000 tons/day in mid-February. From the point of view of power generation, affected by the epidemic, enterprises in the short term operating rate is very low. Take the automobile industry as an example. Although local governments and enterprises have actively arranged for workers to return to work after the holiday, due to the impact of strict epidemic prevention and control measures, workers in major automobile producing areas are delayed in returning to work, and factories cannot resume work in a short period or fail to meet the required capacity. At the same time, due to the control of road transportation and the reduction of the speed of import and export customs clearance, the supply of auto parts and auto production will be sharply reduced, and some supplies will even be interrupted, and the export uncertainty of finished vehicles and auto parts will be greatly increased. Hyundai Motor, for example, temporarily halted production at two factories in South Korea because it could not get cable parts made in China. Similarly, Nissan halted production at its fukuoka plant in Japan and Kia halted production at three plants in South Korea. Fiat Chrysler said it also faced shuttering its European plants at the end of February if conditions did not improve.

In the medium and long term, the impact of the pandemic on global supply chains is manageable. Although the shutdown caused by the epidemic will leave labor idle and increase the labor cost and debt repayment burden of enterprises, with the effective control of the epidemic and the introduction of supportive policies by China and local governments, such as tax relief, manufacturing enterprises outside Hubei will gradually resume normal operations. Hubei province, the region worst affected by the outbreak, is one of China’s automobile production bases, home to several oems and nearly 100 auto parts suppliers. In 2019, about 80% of the capacity of oems in Hubei met the domestic market, and about 90% of the capacity of parts suppliers supplied to local suppliers in Hubei. The impact of the epidemic on automobile enterprises in Hubei province will be significant, but the impact on the global supply chain can be controlled.

The epidemic is approaching the city. How can manufacturers resume work, fight the epidemic and maintain operation in the short term? How to effectively prevent emergencies and enhance the resilience of the supply chain in the long term? We recommend:

1. Steady resumption of work in accordance with local conditions

Targeted work resumption safeguard measures and emergency management mechanism should be formulated to avoid secondary work stoppage

At a meeting of the Standing Committee of the Political Bureau of the CPC Central Committee on February 12, “resumption of work” and “production” were mentioned several times, indicating the central government’s attitude to “resume work and production on the premise of effective prevention and control of the epidemic.” In accordance with the guiding ideology of the Central committee, all localities have issued strict policies to guide the resumption of work. For example, Suzhou has issued regulations for enterprises to resume work during the prevention and control of the Novel coronavirus pneumonia epidemic. While actively preventing the spread of the epidemic, it supports qualified manufacturing enterprises to resume normal production and operation. We suggest that in the process of resumption of work, enterprises should take the work resumption policies of local governments as guidance, and formulate work resumption guarantee measures and emergency management mechanism suitable for their own characteristics.

Where conditions permit, enterprises should use digital means to monitor the resumption of work to support the government’s targeted measures. Hangzhou health code, for example, is the wisdom of the big data and artificial intelligence to make use of the epidemic prevention and control management, enterprises can use in hangzhou health code implements customized for employee management, actively encourage and guide the green code employees back to return to work, red and yellow staff on its own in accordance with provisions of isolation, isolation (green code certification) after the expiry of the partial return to return to work, Effectively prevent the risk of epidemic transmission caused by resumption of work.

Get your priorities straight, get back to work

First, assess the possibility of supply chain bottlenecks or disruptions, timely communicate with suppliers and customers in the upstream and downstream of the supply chain, and immediately identify supply chain bottlenecks after updating customer demand and supplier supply capacity. Secondly, through visual management and statistical analysis of production and operation data after resumption of work, the weak links existing in the internal operation process can be found and improved in a timely manner. Finally, take prompt action to ensure the stable operation of the supply chain according to the developed risk response measures. In the process of resumption of work, enterprises should give priority to solving bottlenecks in the supply chain, and can use platforms such as industrial Internet of Things to realize reasonable allocation of resources. For example, suzhou government has launched the “Work Resumption Communication” platform, which can help enterprises to effectively adjust human resources for work resumption and realize reasonable allocation of human resources.

Strengthen daily HSE safety management

The uncertainty of virus transmission increases the difficulty of HSE safety management, especially in crowded environment such as production and transportation. Safety management requires efficient organization and management measures and the formation of a safety-oriented culture in the enterprise. In this outbreak, a leading auto parts supplier has a 70% return rate. Its successful experience includes: daily safety training, strict safety regulations, comprehensive safety management measures and safety (epidemic) prevention and control system with the general manager as the first responsible person. In view of the characteristics of this epidemic, we suggest that manufacturing enterprises should carry out fine safety management, such as real-time tracking of the health status of employees returning to work; Provide employees with disposable medical masks and goggles, and make them mandatory to wear during work and linked to personal assessment; Gathering of more than two people is prohibited during work; The staff dining room shall be quarantined and disinfected regularly.

Epidemic prevention initiative, encourage and try new office mode

The epidemic has promoted the rapid application of digital office tools. For example, in order to prevent the spread of the epidemic, the daily operation meetings of manufacturing enterprises must be carried out through online meetings. We suggest that manufacturing enterprises take this opportunity to encourage and try the coexistence of multiple office modes for office employees, such as R&D, procurement, finance, IT and other departments, accelerate the implementation of digital office tools and tools, and strengthen the standardization, visualization and transparency of office processes. In the process of trying to work online, enterprises need to achieve clear tasks, unified schedule, supplemented by flexible discussion, to improve the work enthusiasm and work efficiency of employees. Departments that have data security requirements for internal data, such as research and development, and finance, can remotely connect to the internal server through enterprise VPN.

2. Lay a solid foundation to accelerate the improvement of supply chain operation efficiency and management capability

The epidemic has put many enterprises in trouble and exposed the inadequacies in normal supply chain management. At the same time, for the operation of the transformation of the enterprise to create a good opportunity, so that the enterprise up and down, to meet the change.

Reduce lead time and increase profitability

The lead time of supply chain refers to the time between the customer placing the order and the enterprise completing the delivery of the order. The “gap” between each link of enterprise supply chain is too large, which will lead to too long lead time and inventory cycle. Once an emergency occurs, it is difficult for enterprises to make a quick response. At the same time, the cash flow occupied by a large amount of backlog inventory will affect the ability of enterprises to resist risks. Therefore, we suggest manufacturing enterprises to develop appropriate supply chain strategies and improve supply chain efficiency, shorten the lead time, so as to improve the risk resistance and profitability of enterprises.

Integrate and optimize the number of suppliers, establish the supplier information sharing mechanism and integrate the supplier data platform

With the increase of the complexity of enterprise supply chain, the number of suppliers also increases rapidly, and the difficulty of enterprise supplier management and information communication increases. The outbreak will directly lead to the uncertainty of long-term demand. We suggest that enterprises should define the supplier management strategy, optimize the number of suppliers, and establish the supplier information sharing mechanism and data sharing platform. Based on the matching of resources between market demand and supply capacity, the elasticity and anti-pressure capability of supply chain are enhanced, the impact of demand uncertainty on supply chain management is reduced, and the goal of “benefit maximization and risk minimization” is achieved. For example, a world leading automobile manufacturers through strict supplier selection and integration, to achieve only 200-300 parts suppliers, through the ERP system and the APS system main supplier of the finished product warehouse, real-time access to material supplier information, effectively improve the timeliness of information transmission, realize the online real-time monitoring, according to the order demand actively, Pull warehouse materials/supplier parts.

3. Improve the risk management ability of enterprise supply chain systematically

After the baptism of the epidemic, more business operators realize the importance of supply chain risk management. We suggest that enterprises systematically improve risk management, clear supply chain system emergency strategy, so that enterprises in the face of various emergencies to make a rapid response.

Carry out risk analysis and construct emergency strategy of supply chain system

The risk analysis of supply chain is to construct the emergency strategy of supply chain system based on the probability of past events, using computer simulation, and based on the assessment of risk types and potential hazards. We suggest that enterprises regularly obtain industrial historical data such as market and logistics through the industrial Internet platform and combine with their own production and sales data to establish a risk prediction model. Through simulation and deducation analysis, they can judge the changes in capacity demand and raw material supply bottlenecks, and make planning and scheduling in advance to avoid risk problems.

“Constructing the emergency strategy of supply chain system” plays a key role in the process of the whole supply chain system coping with risks. The emergency strategy of supply chain system is to study the management methods that can reduce the impact of risks in the case of risk interference. According to the nature of the Supply Chain system emergency strategy, it can be divided into “Responsive Supply Chain” and “Robust Supply Chain”. The former means that the normal operation of the enterprise has the ability and speed to quickly resume production and service after the risk interference, while the latter means that the enterprise has the stability to maintain the original production and service state after the interference.

Formulate countermeasures and establish an emergency mechanism

Under the guidance of the emergency strategy of the supply chain system, enterprises need to develop countermeasures for various types of risks. The establishment of a risk response mechanism for different risk events will affect the setting of supply chain indexes such as safety inventory, number of suppliers and common design of parts. In response to regional accidental risks such as novel Coronavirus outbreak, Responsive Supply Chain reduces the system’s occupation of resources by adopting flexible management methods. For example, combination substitution of multiple Supply and service modes is adopted; The Robust Supply Chain maintains the stability of the system by increasing the occupation of resources, such as adding alternate suppliers, purchasing in Multiple regions, and doing Dual Sourcing or even Multiple Sourcing to create a more stable and secure Supply Chain.

4. Embrace digital transformation and improve the transparency of supply chain

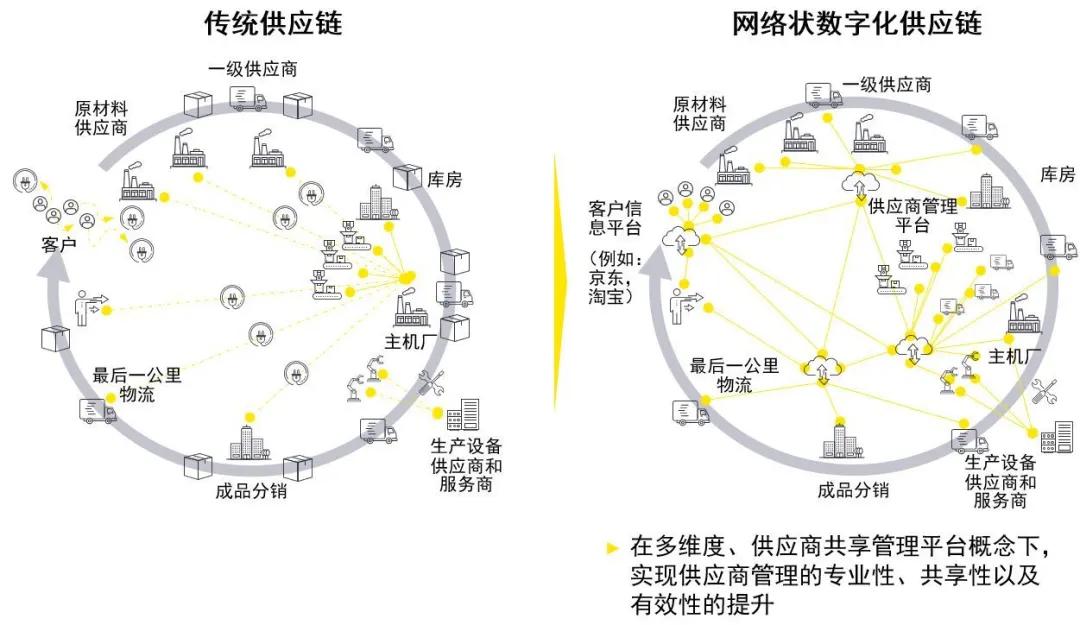

With the maturity of digital technology, digital technology has been filled with every corner of our life. Digital technologies are driving the digital transformation of supply chains, and the list of success stories is endless. The information transmission of traditional supply chain is only limited between raw materials and finished products in the production system, and this linear transmission path has low flexibility. The digital supply network based on digital technology adopts the matrix structure of interworking and has higher flexibility. This structure eliminates the traditional linear transmission route and maximizes the efficiency of information dissemination in response to changing customer and market needs (Figure 2). For example, relevant parties in the supply chain can conduct real-time analysis of supply and demand data based on the digital supply network, so as to avoid communication lag, timely respond to changes in demand and supply caused by the epidemic, realize effective allocation of resources, and ensure the normal and orderly production of enterprises.

It is certain that with the stabilization of the epidemic, enterprises will pay more attention to the application of digital technology and put forward higher requirements for data analysis. We suggest that enterprises make digital development goals, conduct digital capability assessment, sort out digital solutions and improvement schemes suitable for their own characteristics, select and apply suitable digital tools with a specific goal, and achieve transparency and efficiency of enterprise operation process. For example, transparent and efficient supply chain management improves the production rate of enterprises, reduces the cost of idle material, frequent line change and seasoning caused by the failure of materials, and effectively guarantees punctual delivery. In addition to the cooperation among various departments within the enterprise, the establishment of digital supply chain is also inseparable from the cooperation between companies to realize the upstream and downstream cooperation, information sharing and resource coordination of the supply chain.

conclusion

The epidemic will also stimulate the potential of enterprises, accelerate the transformation of supply chain, improve the operational efficiency of supply chain and the level of crisis management, thus injecting new vitality. We believe that after the baptism of the epidemic, China’s manufacturing industry may usher in new glory!