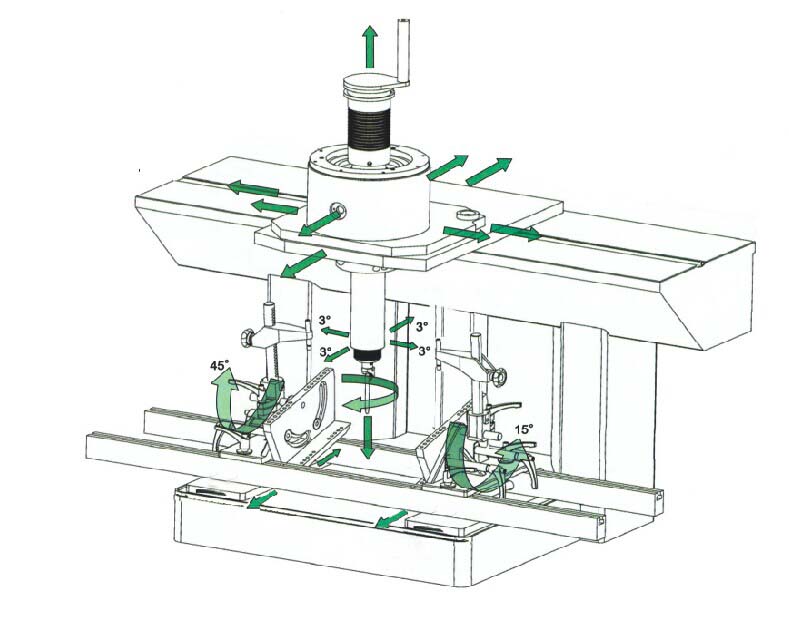

The utility model relates to a valve guide hole centering, using air floatation rapid adjusting positioning, tool rod free-swings or spindle set free oscillation, a level and stepless speed regulation of vertical engine cylinder head valve seat machining machine tool maintenance, purpose is to make sure that the roundness and valve seat ring seal cone taper requirement, and can ensure that the valve seat seal cone and valve guide hole center line of the circle Dynamic requirements. Its structure are mainly lathe bed, boring head, specific, boring tool rod, cutting tools, locating mandrel and pneumatic components, boring head including rigid boring head and spindle sleeve guide bush universal swing boring head, boring cutter bar including rigid tool rod and universal tool rod, can translational or rotational workpiece relative bed mesa, artifacts can also around two mutually vertical and parallel to bed mesa axis adjustment Angle, universal swing boring head Swing or universal tool rod can be random correct positioning of spindle and valve guide hole orientation and positioning error, high centering precision, under the hi

gh rotation accuracy of drive, after feeding mechanism of fine feed, high machining accuracy, using this machine repaired engine cylinder head valve seat completely meets the requirement, it is a ideal equipment in the engine cylinder head valve seat repair. The TL120 Power has a benefit of air floating table bars. Thus adding faster setup time and effortless shifting of any size cylinder head. This feature decreases operator fatigue and increases productivity. ◆Machining capacity .55″/16mm to725″/120mm. ◆Fitted with the new tooling that decreases the cutting force by 30%, this machine will cut the hardest seats. ◆Patented lightweight workhead: built-in spindle motor and triple air-float automatic entering system. Minimal workhead inertia and maximal floatation for unmatched centering sensitivity. ◆Build-In spindle motor. Broad torque ratings from lowest RPM. ◆Fully integrated spindle motor: Infinitely variable spindle speed, 0 to 1000r.p.m., with sensorless Vector Flux Control in open loop (extremely broad torque ratings from lowest r.p.m.). Digital spindle rotation read out.